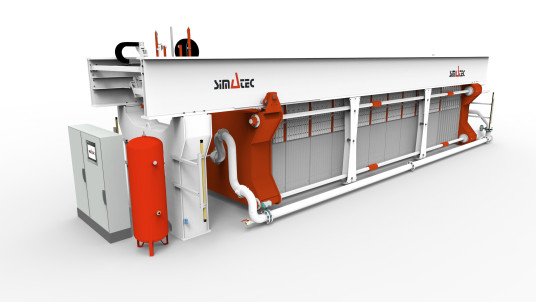

Chamber filter press KFP-U

The high-performance filter press for demanding environmental applications

The chamber filter press KFP-U is the most powerful model in the Simatec portfolio. It was developed for industrial applications with high throughput, automated processes and intensive use – especially in wastewater treatment, water treatment, chemicals and mining.

Upper beam design with free maintenance access

The load is transferred via a robust upper beam structure. This leaves access to the plate pack free from all sides, which greatly facilitates maintenance, inspection, cloth replacement and cleaning and reduces mechanical damage.

Multifunctional automation trolley

A centrally controlled trolley combines several core functions:

- Plate opening: Automated single or composite opening with precise time management.

- Vibration system: Impulse-assisted cake release for materials that are difficult to empty

- Cloth washing system: Integrated high-pressure cleaning for constant cloth permeability and cycle optimization.

- Plate crane: Internal lifting system for quick replacement of individual plates – without external aids.

Hydraulic system with four corner cylinders

Symmetrical force transmission via four hydraulic cylinders at the plate corners ensures even loading of the press frame. This increases frame stability, minimizes deformation and improves operational safety – even during pressure or temperature peaks.

Double-beam core for high frame rigidity

The beam structure is designed for high mechanical loads and supports plates, carriages and additional systems without deformation. This reduces vibrations and ensures precise movement sequences – even in continuous operation.

Side-opening plate package

Instead of linear movement, the plates are opened by swiveling or extending sideways. This saves space, improves access and speeds up maintenance work.